Mechanical Workshop

Since 1985, Gennaro has developed the mechanical processing department, focusing in particular on naval reconditioning.

In detail we are equipped with:

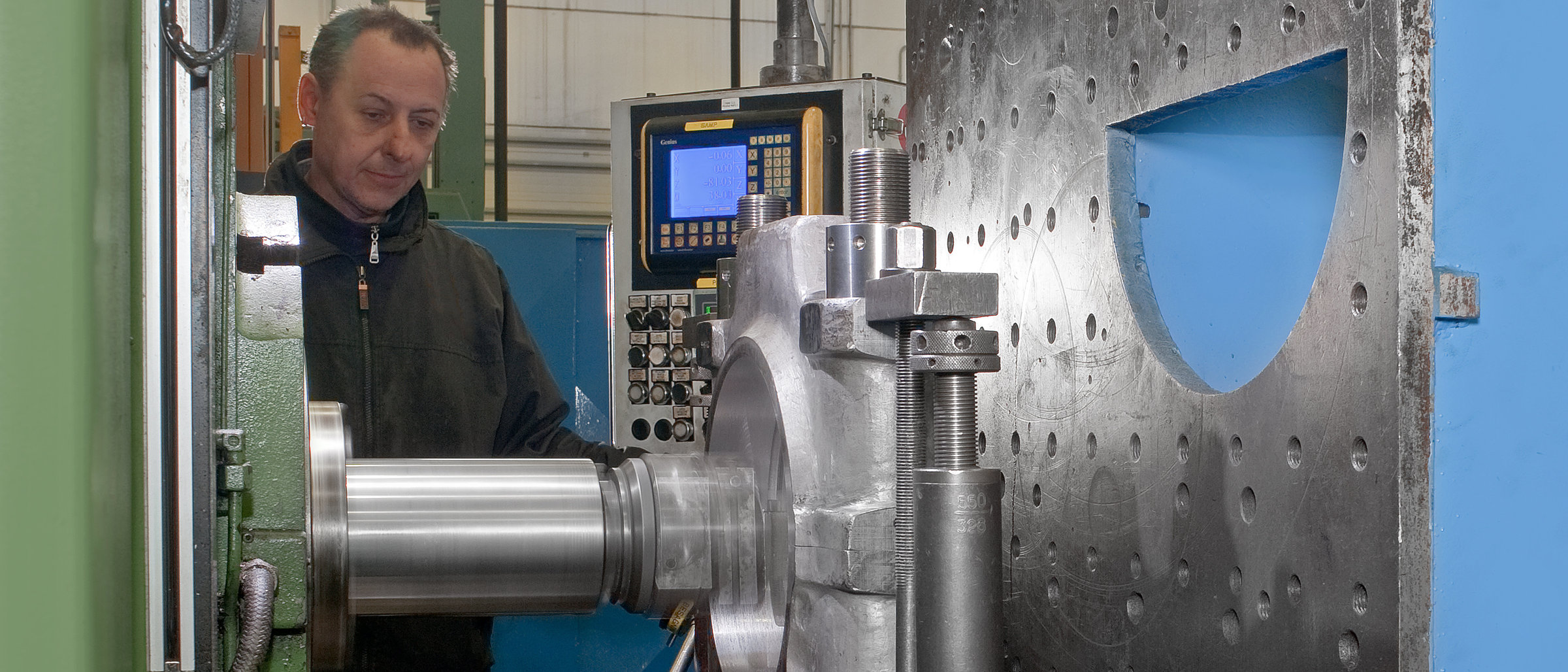

- Vertical lathes with diam. Maximum turning 1700mm

- Parallel lathes with maximum length 12000mm and turning length 1400mm

- Fixed and mobile bench boring machines, traditional and 4-axis CNC

- Tangential grinding

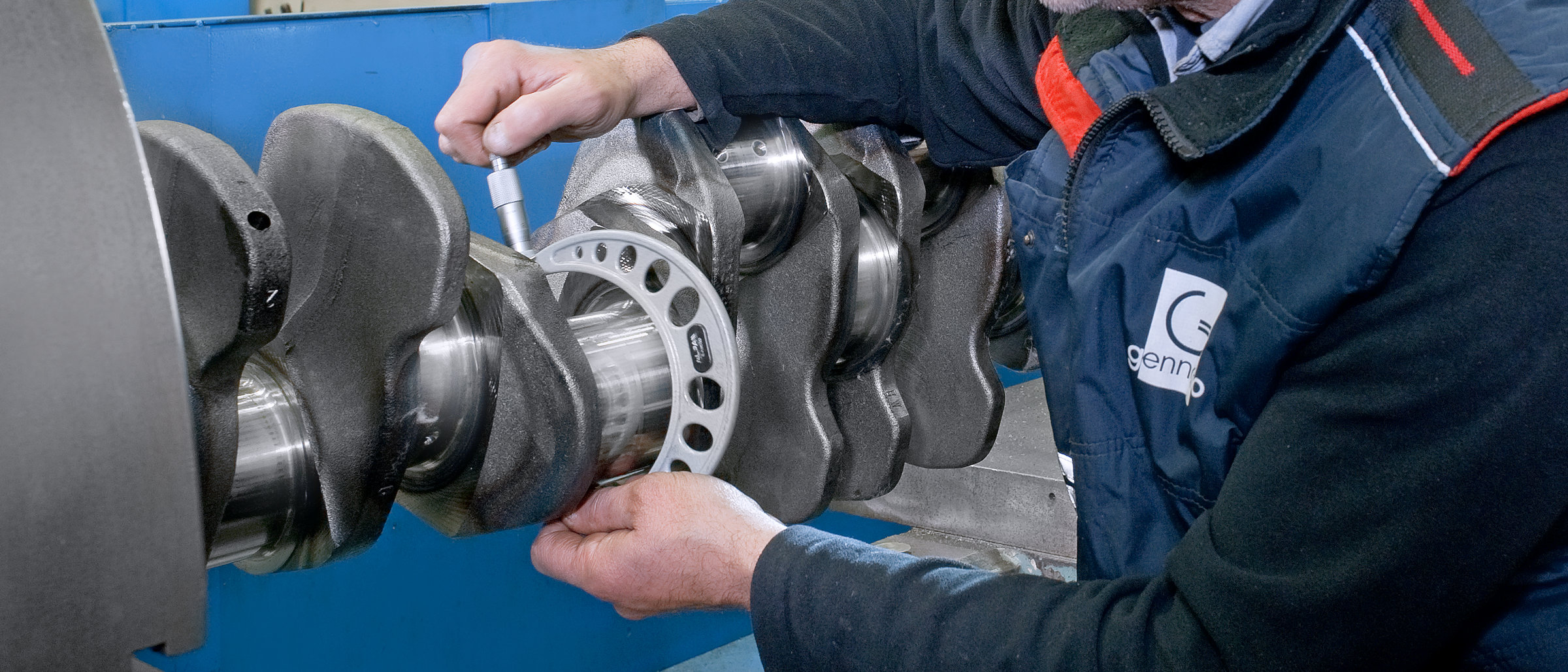

- CNC orbital grinding for crankshafts up to a length of 12000mm

Inside the mechanical workshop there is also a team of technicians specialized in on-site processing with specially created machinery: boring, turning, grinding even of complex details such as crankshafts, rotors or vertical shafts for turbines. Among our equipment there are also machines for the heat treatment of steels according to DNV GL certified procedures as well as SKF Laser alignment tools for the on-site verification of bases, motor/gearbox groups, propeller door lines, etc.

We operate constantly under the surveillance of the most important naval registers and our technicians are RINA level II certified for Non-Destructive Testing (Ultrasound and Dye Penetrant Test).