On Site Machining

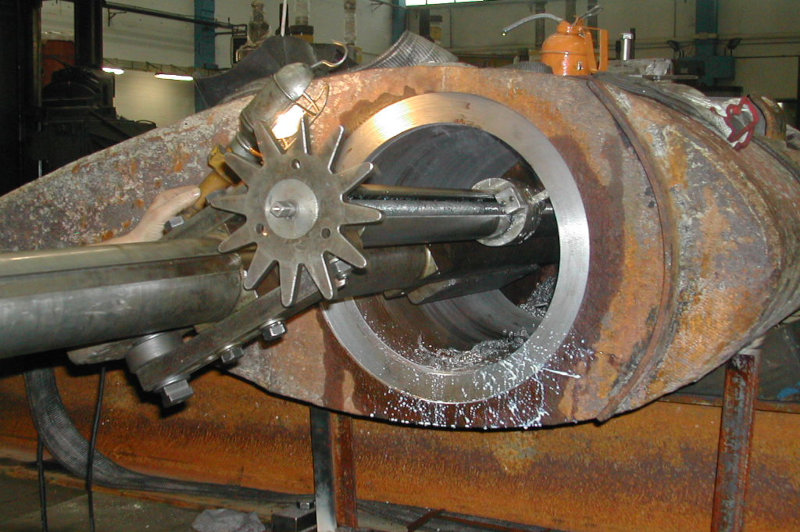

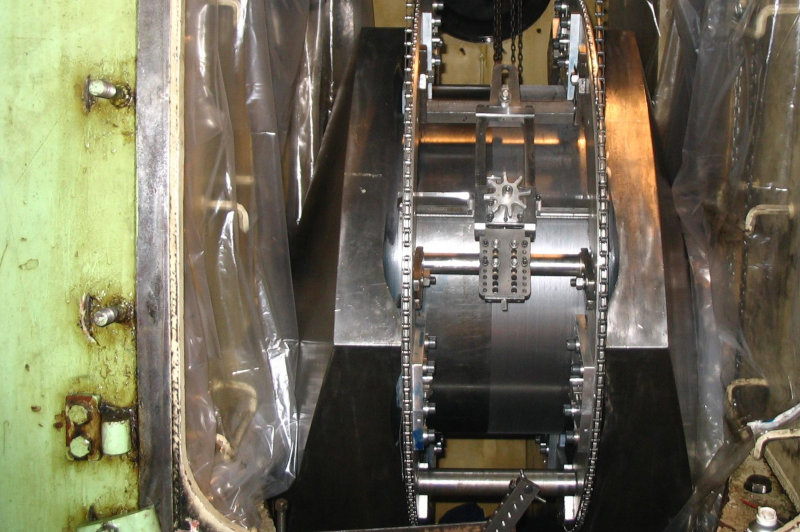

This is certainly one of our main activities: turning and grinding on site for connecting rod pin or main journals on crankshafts, propeller shafts, rotors in general or vertical shafts for turbines.

We have the best equipment for flattening liner surfaces on Main Engines and Diesel Generators, boring in place of upper or lower liner housings, engine bases, bearing housings, etc.

The great experience of our technicians as well as the high corporate flexibility allow us to modify and/or integrate our equipment based on the specific needs of the customer.

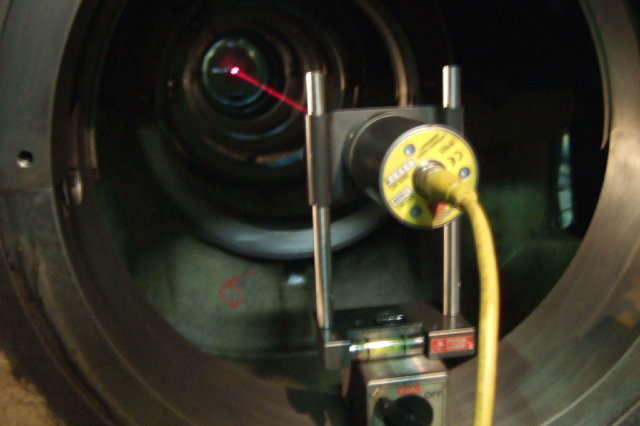

Upon completion of the processing we are able to verify the correct geometric alignment of bushings, cases, axles, motor-alternator or motor-reducer groups, through the use of SKF Laser instrumentation with final release of the alignment certificate.

Since 2024 we have been authorized to create foundation floors (chocking) with HENKEL Fixmaster certified products.